Sometimes more than one product comes to market from a single PCB. A budget version may not ship with some parts (e.g. bluetooth) or may have different configuration (E.g. RAM). Assembly variants gives the engineer a structured method to manage this during the design process in a way that all of the output systems will understand. For example, a part that is not fitted in a variant should not show in the 3D viewer and nor should it appear in the bill of materials or assembly drawings.

- Support for multiple product variants throughout the software suite.

- Quickly create and edit variants in the design explorer module.

- Set the fitted status of parts or specify replacement parts in a variant.

- Variant comparison report details all changes from the base design.

Alternate Parts

In Proteus, you can also specify alternate parts in different variants provided that they are pin-compatible with the original part. As with normal use you would do this in design explorer where you can change properties per variant.

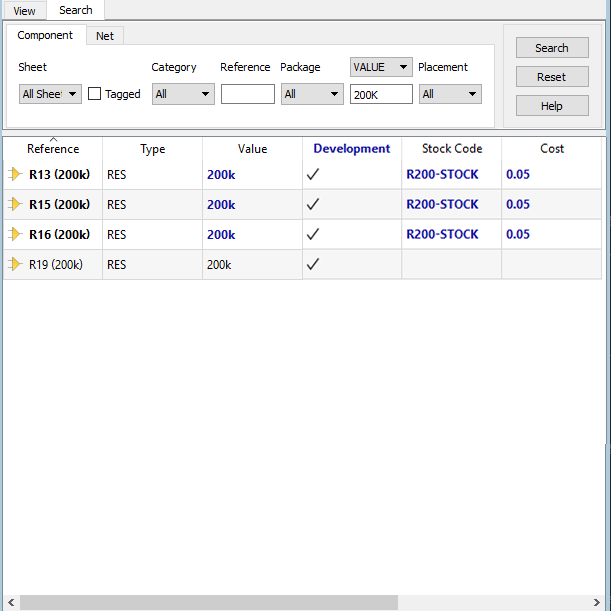

Imagine for example that you wanted a different amount of memory in different product configurations. Here we are not editing the fitted status but changing the part value and also editing additional properties like stock code and cost.

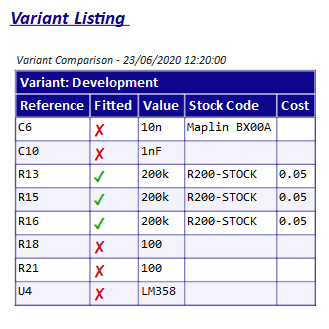

Variant Comparison

If you have several variants of a board it's sometimes tricky to keep track of everything. Fortunately, the variant comparison report tabulates all the differences between each variant and the Base Design. Since all project design is done in the base design this tells users where each variant diverges from the common schematic.

The report itself can be generated automatically from the Project Notes module and can be updated or refreshed with a mouse click at any time.

Output

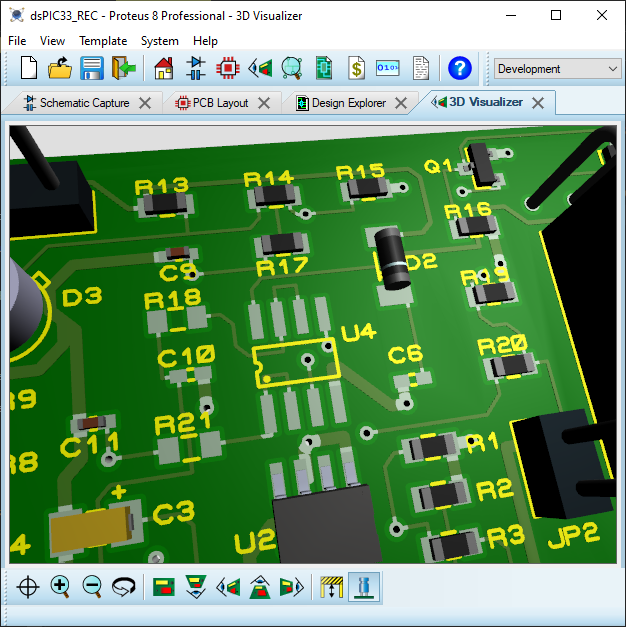

All of the output systems in Proteus are aware of and will honour configuration of assembly variants. On the schematic side this means that the bill of materials module will include the current variant in the header block, not fitted parts will not be listed and alternative parts correctly applied.

On the layout side the 3D Viewer will not include non-fitted parts and they will not be exported in a STEP or IGES assembly for MCAD. Similarly, the Pick and Place file and the assembly drawings will not include parts deemed as not fitted in the currently selected variant.

Examples

There are plenty of different uses for assembly variants in your project design. Here's a few examples:

- Product Configurations: This can either be different functionality in different variants (e.g. no bluetooth module) or more capacity (e.g. more RAM).

- Testing Variants: Set up different test configurations for the product (e.g. power supply test). Alternatively, you may want to test two prototypes using different (pin-compatible) parts to evaluate performance,noise,efficiency etc.

- Versioning: Use different pull-up/pull-down resistors on MCU pins to inform the firmware what version of the PCB is present.

Ask An Expert

Ask An Expert

Have a Question? Ask one of Labcenters' expert technical team directly.