Introduction

Tin Whiskers. These feline filaments have felled satellites and disabled a nuclear power station. But have you heard of them before?

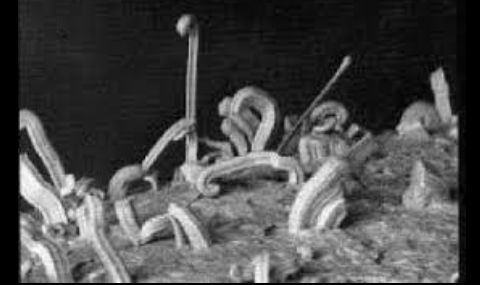

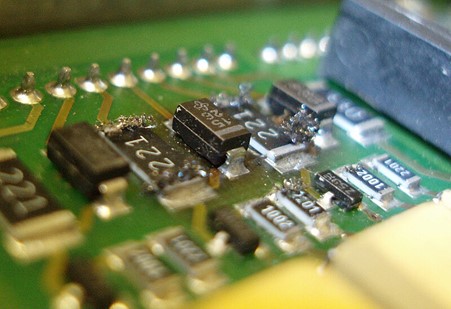

These tiny needle-like strands erupt and extrude from the surfaces of metals, potentially creating short circuits if they reach to other nearby components (and thereby possibly disabling or degrading circuits as a result).

Causes

The phenomenon is not yet well understood by science, but it is known that certain conditions favour growth:

- The growths are more prevalent in tin, but can occur with other types of metals as well.

- Adding lead to the metal alloy reduces prevalence, and as a result Tin Whiskers are less common in leaded solder than they are in lead-free solder. For this reason, certain high-reliability industries (such as spaceflight, aviation and medicine) are exempted from the RoHS directive banning lead in solder.

- High altitudes and compressive mechanical stress are also known to be contributing factors.

Problems

Tin Whiskers range in diameter from 0.006ųm to 10ųm (typically ~1ųm - 50 times thinner than the average human hair) and can be as long as 10mm (typically 1mm). They grow from the base (not the tip), and as they are more prevalent when the source metal is under compressive stress they would appear to be a form of extrusion. Rate-of-growth can be as high as 1mm-per-year.

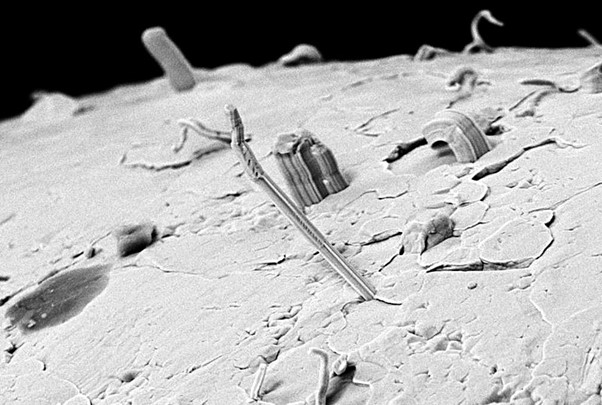

Silver Sulphide Whiskers.

Silver Sulphide Whiskers.

Apart from directly growing between contacts and causing a short circuit, the whiskers can also break off and even become airborne, landing on circuits and then causing short circuit; this has been known to happen in server rooms, where whiskers can grow beneath zinc electroplated raised floor tiles and then become airborne when someone enters the room and walks on the floor.

Zinc Whiskers on Zinc-Coated Steel.

Zinc Whiskers on Zinc-Coated Steel.

Although the whiskers themselves will only conduct less than about 50mA before fusing open, they can under certain conditions initiate a metal vapour arc (plasma) which can conduct hundreds of amps and be extremely destructive.

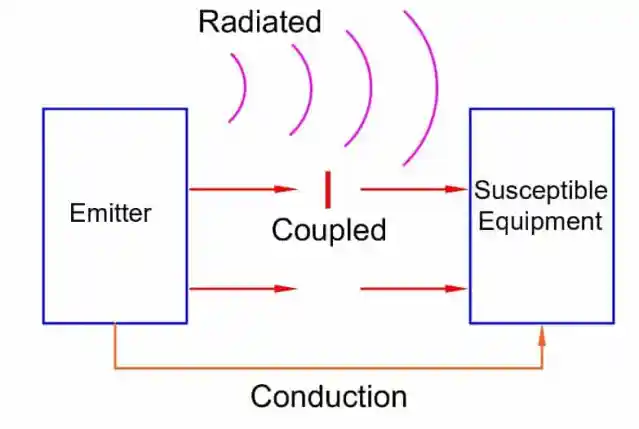

In high frequency circuits (above 6GHz) whiskers can also act as miniature antennas, affecting circuit impedance and causing reflections.

Mitigation

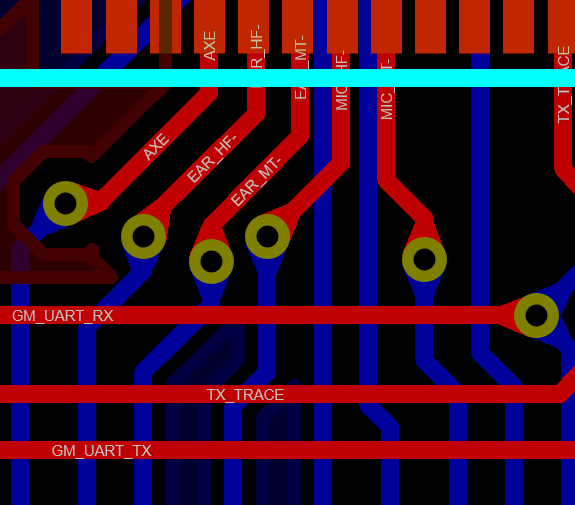

In the past lead was used to mitigate growth, however this is no longer allowed in many situations due to legislation intending to reduce the amount of lead entering landfills. Additional mitigation strategies include conformal coating, and even stripping pure tin coatings from components and replating with nickel. Components can be placed further apart (less dense PCB) to reduce the likelihood of a whisker reaching another component. Reducing the presence of mechanical stress placed on PCBs is also recommended.

Summary

Although Tin Whiskers may not be a primary concern for many engineers, they can be an important consideration in the design and manufacturing process of high-reliability industries. This is particularly true if the board is intended for long term use or environment conditions are uncertain.

All content Copyright Labcenter Electronics Ltd. 2024. Please acknowledge Labcenter copyright on any translation and provide a link to the source content on www.labcenter.com with any usage.Get our articles in your inbox

Never miss a blog article with our mailchimp emails